Passivazione Per Acciaio Elettrozincato

La passivazione per l'acciaio zincato è la preparazione del prodotto per la preparazione della superficie priva di cromo al rivestimento funzionale, quindi può ridurre l'impronta ambientale per le acciaierie.

la passivazione, applicata alla lamiera zincata, può aggiungere un'eccellente protezione dalla corrosione durante lo stoccaggio e il trasporto.

la passivazione può raggiungere i requisiti dei clienti, ad es. Umidità e resistenza al calore, resistenza alla corrosione, resistenza al calore e così via.

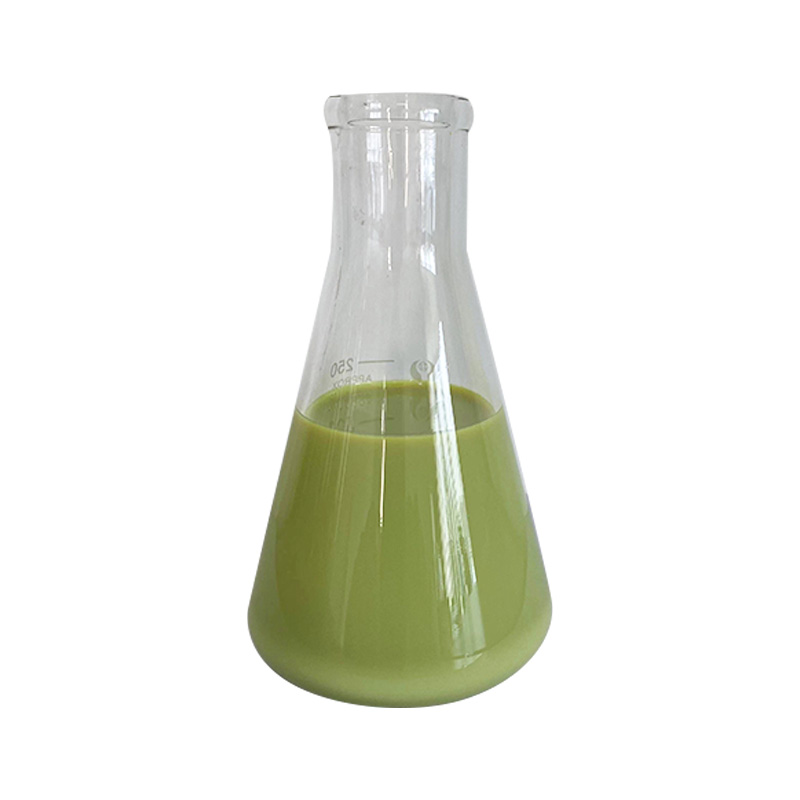

Bt-2363 is a kind of dark green acid environmental protection trivalent chromium passivation liquid, by trivalent chromium salt, organic silicone resin, accelerator, crosslinking agent and special additives refined. , can make the metal has very reliable corrosion resistance, heat resistance, can be very good adhesion on the coating, used to improve the metal color resistance during the storage or transportation of strip steel. Without hexavalent chromium or oxidant, it can meet the requirements of products exported to Europe, the United States, Japan and other places. Can pass 96 hours of neutral salt spray test. Suitable for all kinds of hanging or rolling plating zinc acid, alkali zinc plating production line, rolling plating small passivation is not easy to scratch. Passivation solution can be used for a long time as long as it is replenished according to consumption and does not need to be replaced normally.

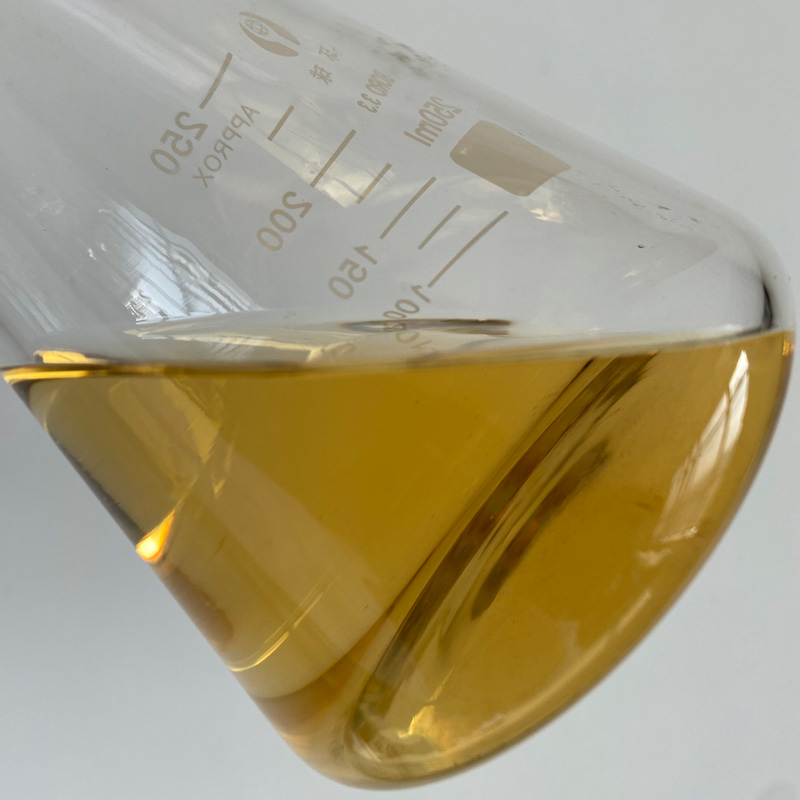

bt-2359 is a white to yellow-green emulsion free of chromium ions, mainly composed of organic resins, silane, corrosion inhibitors and additives, rohs standard, is a new generation of environmentally friendly products to replace chromate passivation. Excellent corrosion resistance and coating adhesion to meet subsequent process requirements.

bt-2363, bt-2359, CL-2360 common typical process: cleaning - cleaning - extrusion drying or drying - passivation treatment - drying (PMT 80-120℃)

The same aspects of bt-2363, bt-2359 and CL-2360 can produce a colorless conversion film on the coating to resist erosion

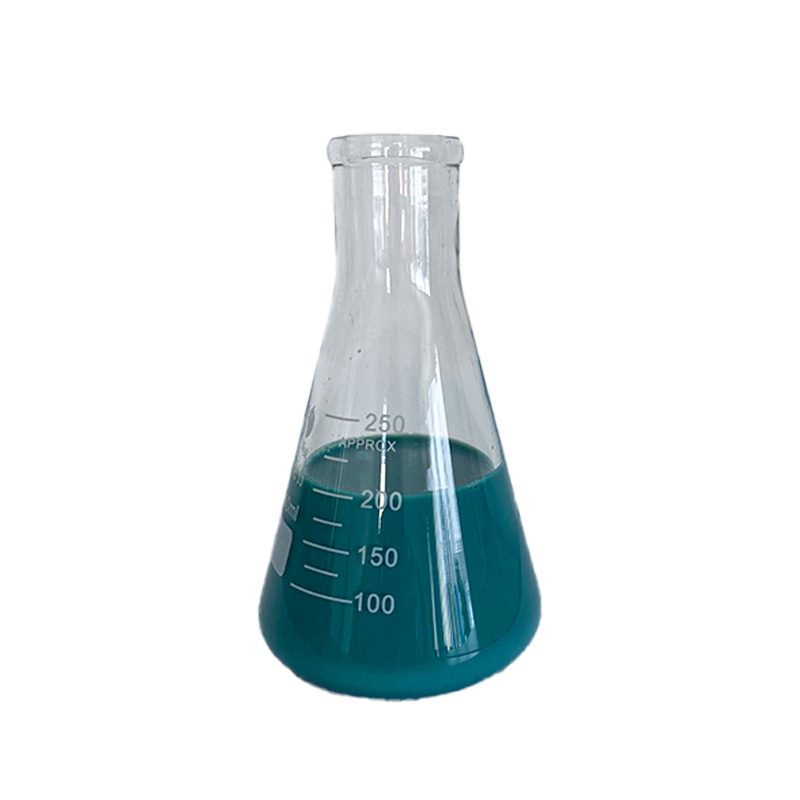

CL-2360 is a white to yellow-green chrome-free emulsion consisting primarily of organic resins, silanes, corrosion inhibitors, and RoHs-compliant auxiliaries. It is a new generation of environmentally friendly products that replace chromium ions and avoid fingerprint attachment. Compared with the above two products, this product has the strongest resistance to fingerprint adhesion

Trivalent chromium passivation, as the name suggests, it contains chromium, it not only has the stability and color of hexavalent chromium, but also the pollution degree is much smaller than hexavalent chromium, trivalent chromium salt spray whether it is made of aluminum or die casting aluminum can easily meet the requirements, but because it still contains chromium, so now in some aluminum province environmental protection departments began to require the elimination of trivalent chromium, Chromium-free passivating agents are required. No chromium passivation agent, first no chromium, then will avoid chromium pollution, now no chromium passivation agent is divided into manganese, pick system, rare metal system, in the domestic pretreatment industry development time is not very long, his stability and hexavalent chromium and trivalent chromium are incomparable, it is understood that no chromium passivation agent do die casting aluminum salt spray over 24 hours, at the same time because there is no chromium, Now many non-chromium passivating agents are produced without color, without color of course, there is no way to control the production process, once the problem is unimaginable consequences. Because of the national environmental protection requirements, some large aluminum factories and related manufacturers began to require their pretreatment passivation plants must use chromium-free, which also created the perfection of chromium-free passivation agents, now chromium-free passivation agents also began to have color, I think this is just the beginning, because of the national policy requirements, to the later will develop more and more vigorous